Variable Air Volume Terminal Unit

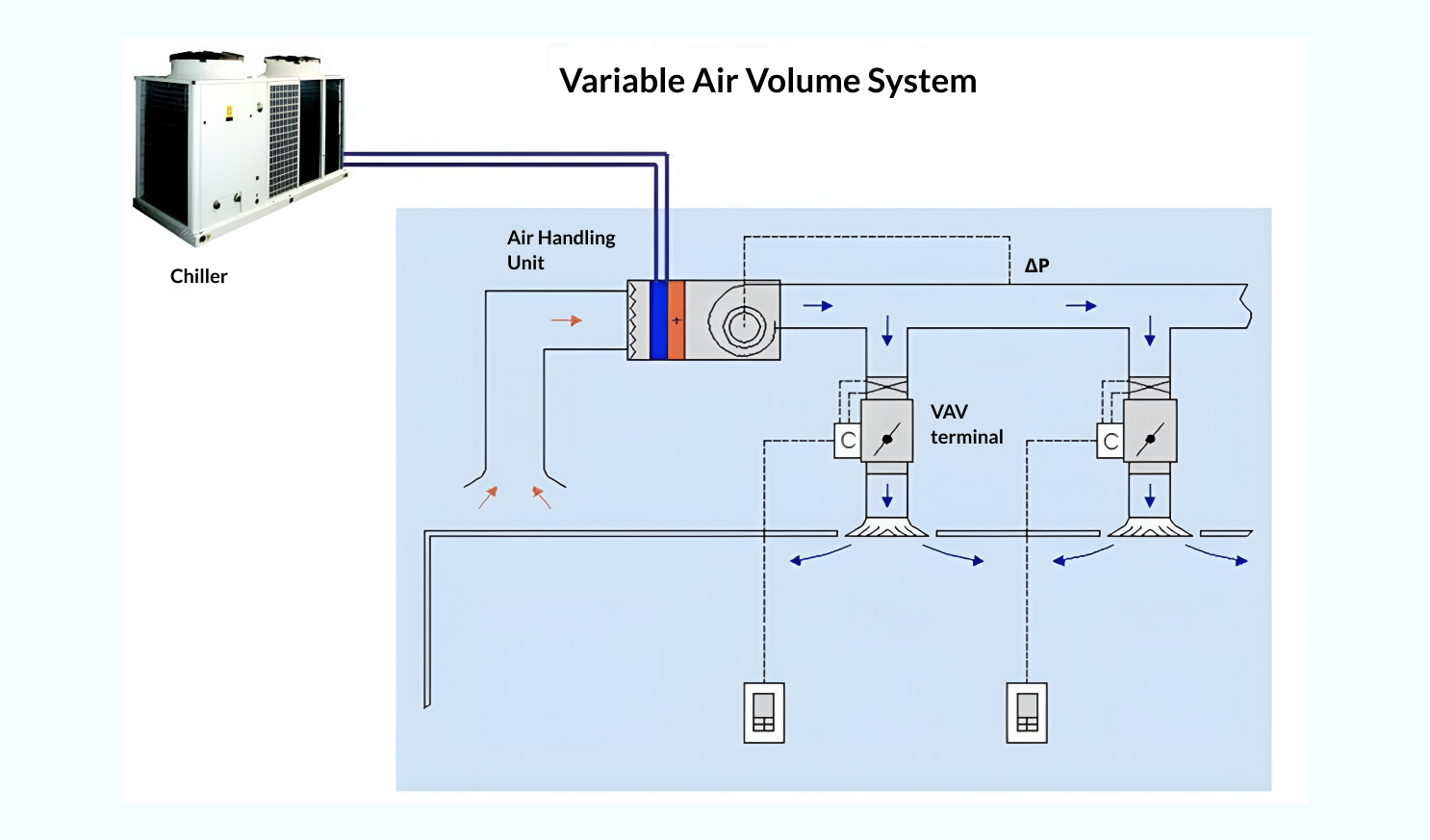

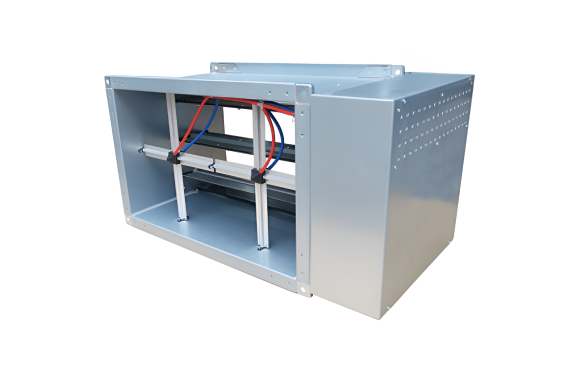

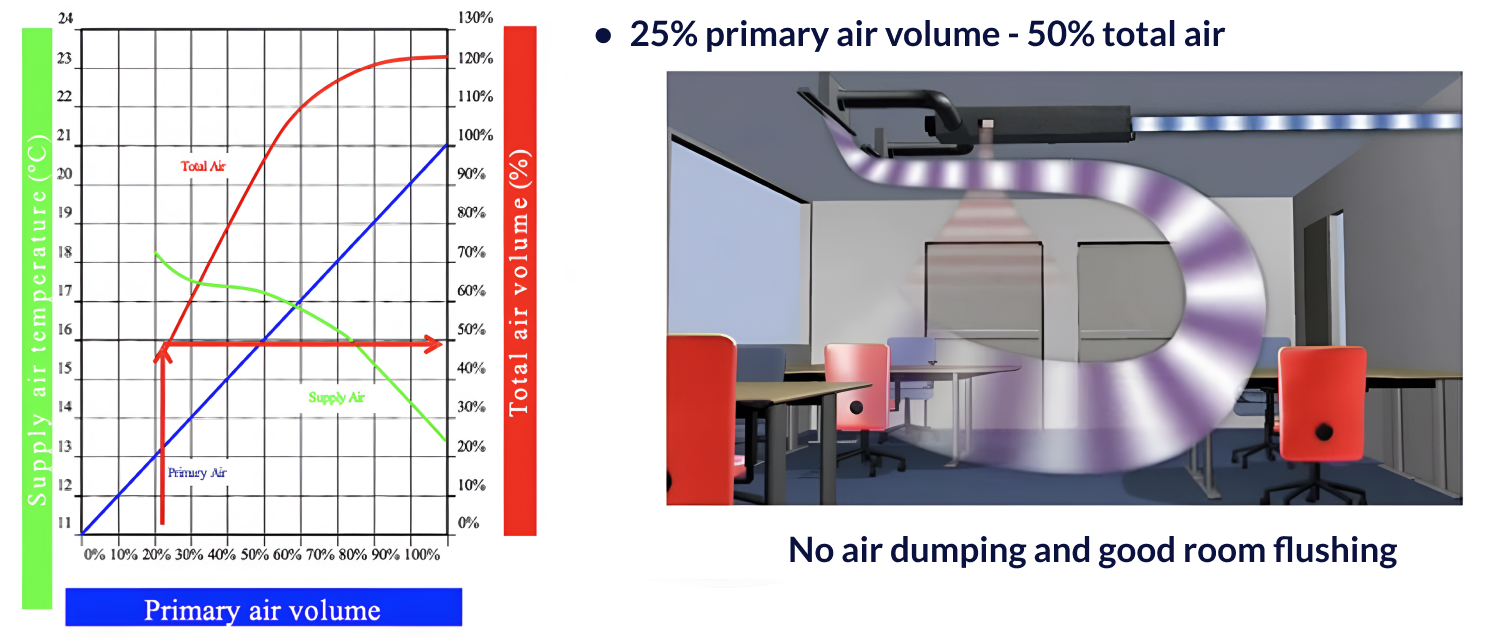

The performance of the VAV terminals and their controls is critical to the performance of the overall VAV system. Barcol-Air is known for their leadership to create an indoor climate which offers an optimum system in terms of comfort, pressure, IAQ and energy efficiency.

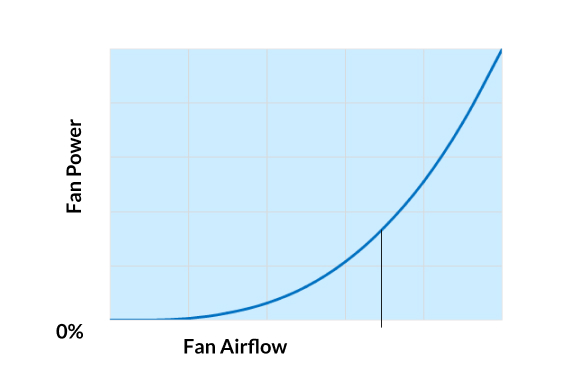

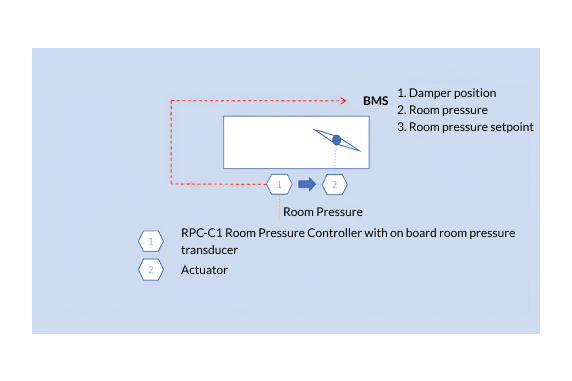

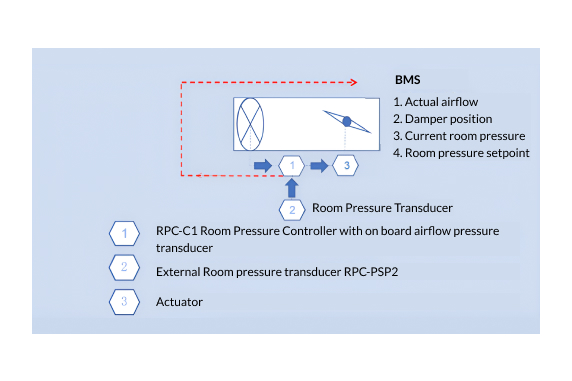

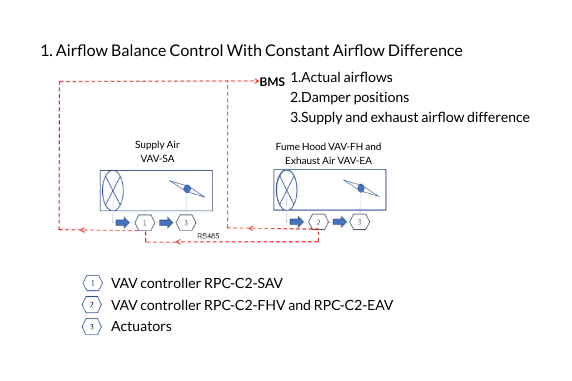

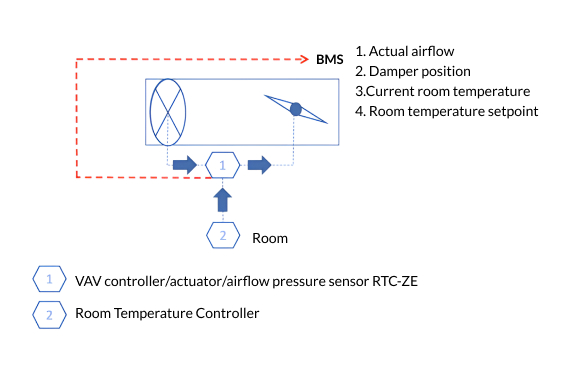

In order to vary the amount of Pressure, IAQ, Cooling or Heating provided to a room: