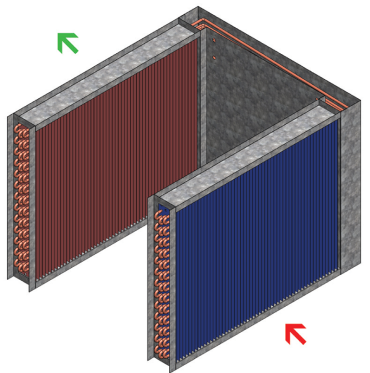

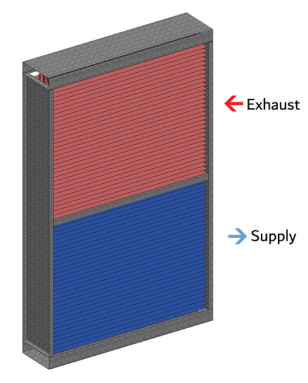

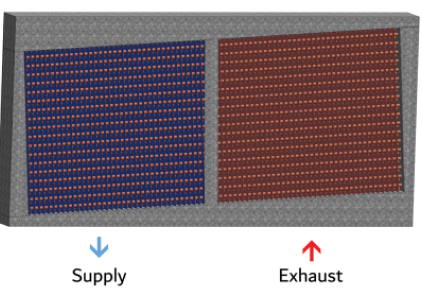

Heat Pipe

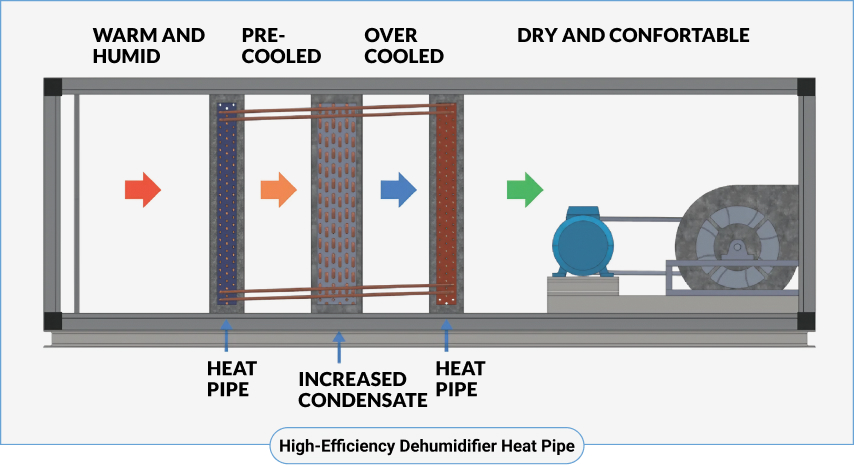

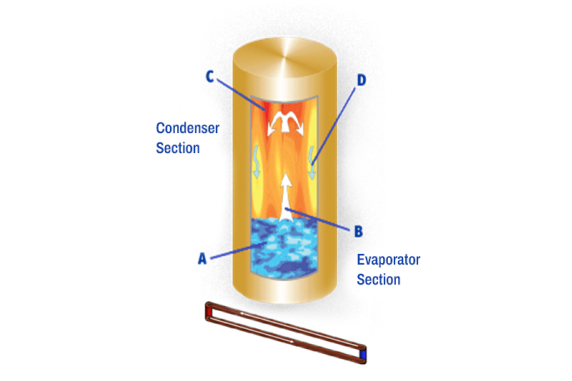

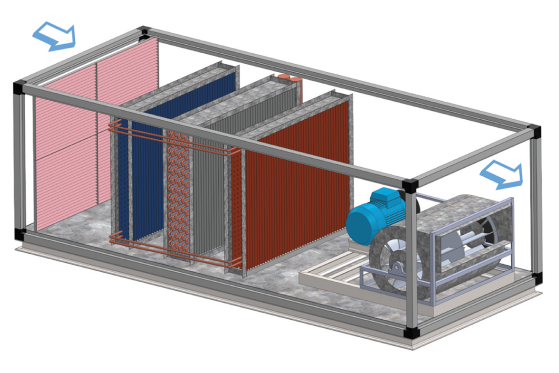

Heat pipes is a heat-transfer passive device that employs phase transition from one location to another within closed-loop systems. They are used as heat recovery system.

Heat Pipe transmits heat using capillary & gravity action and the laws of thermodynamics. It is made up of a working fluid within an evacuated tube. The tube’s material is of high thermal conductivity, moving working refrigerant from the cold end (condensation) to the hot end (evaporation) of the heat pipe. The refrigerant within a heat pipe needs to have a low boiling point and a high latent heat of vaporization.