Heatex rotary heat exchangers are carefully designed to meet the demands of each specific application and maximize energy recovery.

High Efficiency

Rotating heat exchangers provide very high sensible and latent efficiencies.

Minimal Cross Contamination

Seals and purge sectors minimize the cross-contamination of exhaust air into the supply air.

Low Freezing Risk

Rotary heat exchangers offer very low Freezing risk as the wheels by definition defrost themselves.

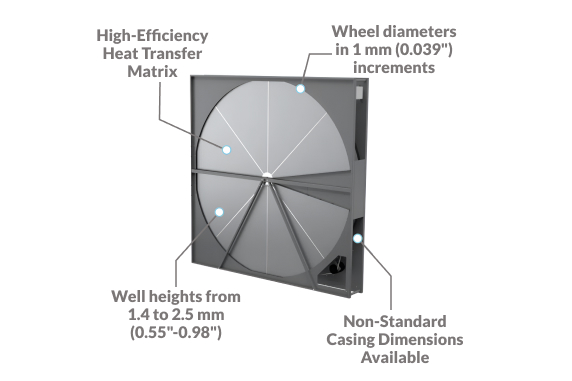

Rotary Type Air to Air Heat Exchanger Features

All Heatex rotary heat exchangers share these features :

- Heatex high-efficiency heat transfer matrix

- Wheel diameters are available in 1 mm (0.039″) increments

- Numerous well-heights from 1.4 to 2.5 mm (0.55″ – 0.98″)

- Non-standard casing dimensions

Depending on the application, you might need a certain rotary model, including options.

Choose Your Model

Every Model has a clear advantage, depending on your application needs.

| Heatex Model | E & O | EQ & EV | EN |

|---|---|---|---|

| Description | E has one of the most compact casings on the market. Each wheel size has an optimized casing size. | EQ and EV facilitate on-site installation or in narrow spaces. It also provides for lower transportation costs due to its segmented design. | EN holds a smaller diameter hub and bearing, which maximizes the airflow for small residential air handlers. |

| Airflow capacity | 200 – 90 000 Nm³/h (125 – 56 000 CFM) |

2 000 – 190 000 Nm³/h (1 170 – 110 000 CFM) |

50 – 2000 Nm³/h (30 – 1 177 CFM) |

| Rotor design | One piece | Segmented | One piece |

| Configuration |

|

|

Without casing |

| Exchanger orientation |

|

Vertical only |

|

| Rotor diameter | 500 – 2575 mm (19.69" – 101.38") +50 mm (1.97") with casing |

1600 – 4000 mm (47.24" – 157.48")* | 200 – 500 mm (7.87" – 19.7") |

|

|

|

*Local differences may occur.

Options

We offer a wide range of options to suit various applications.

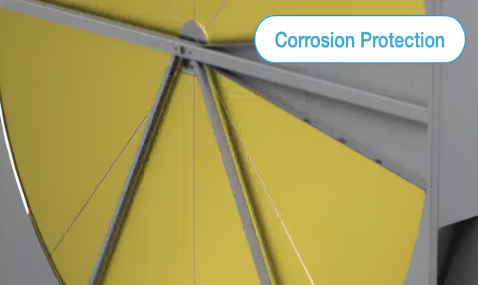

Epoxy & Corrosion Protected Framework

Increase corrosion resistance with a corrosion-protected framework, epoxy-coated wheel, and corrosion-resistant ball bearings.

Purge Sector & Sealings

Models with casing can be equipped with special seals and a purge sector to minimize the cross-contamination of exhaust air into the supply air.

Molecular Sieve

Depending on the application, you might want to enable humidity transfer and add a coating like molecular sieve.

Hatches & Cable Glands

Inspection hatches and cable glands allow for easy access to the motor, belt, and pully for quick inspection and maintenance.

Modbus & Rotation Detector

Depending on the model, we offer constant or step drives with Modbus and a built-in rotation detector.

Power Belt

The Power belt can be used without a tensioning device and is our strongest belt, suited for hot and humid climates..

Product Selection with Heatex Select

Heatex Select enables accurate calculations of the performance of our products under different conditions. Heatex Select is accessible in three ways, online, offline and as a DLL.

Certified Performance

Our products always comply with standards, always perform according to (or even exceed) codes and specifications. Heatex holds several certifications covering product and operation quality worldwide, e.g. Eurovent, AHRI, and TüvSüd. Our products are field-tested and designed to comply with all relevant building codes and regulations. We frequently send our products to independent labs worldwide for inspection and we have our own in-house test rig to regularly evaluate product performance.

Application

Rotary heat exchangers are very versatile and can be found in a wide range of applications. These are just a few examples.

Commercial Ventilation

Residential Ventilation

Spray Paint Booths

Indoor Agriculture

Marine

Industrial Ventilation

Double Rotor

Retrofitting

Comfort Ventilation

Rotary & Plate Heat Exchangers

Heatex quality air-to-air heat exchangers are custom-made and designed to match the customer’s technical specifications. There are two categories of air-to-air heat exchangers, rotary and plate heat exchangers. The plate heat exchangers are further divided into cross and counterflow exchangers due to their different airflow configurations. Depending on the application, rotary and plate heat exchangers have their own distinct advantages.

| Rotary Heat Exchangers | Plate Heat Exchangers |

|---|---|

| Low risk of freezing | Very low leakage rate |

| Humidity transfer | No moving parts |

| Leaving a small footprint in air direction | Minimal service and long lifetime |

| High flow rate capacities | Rapid and easy cleaning |

Double Rotor Setup

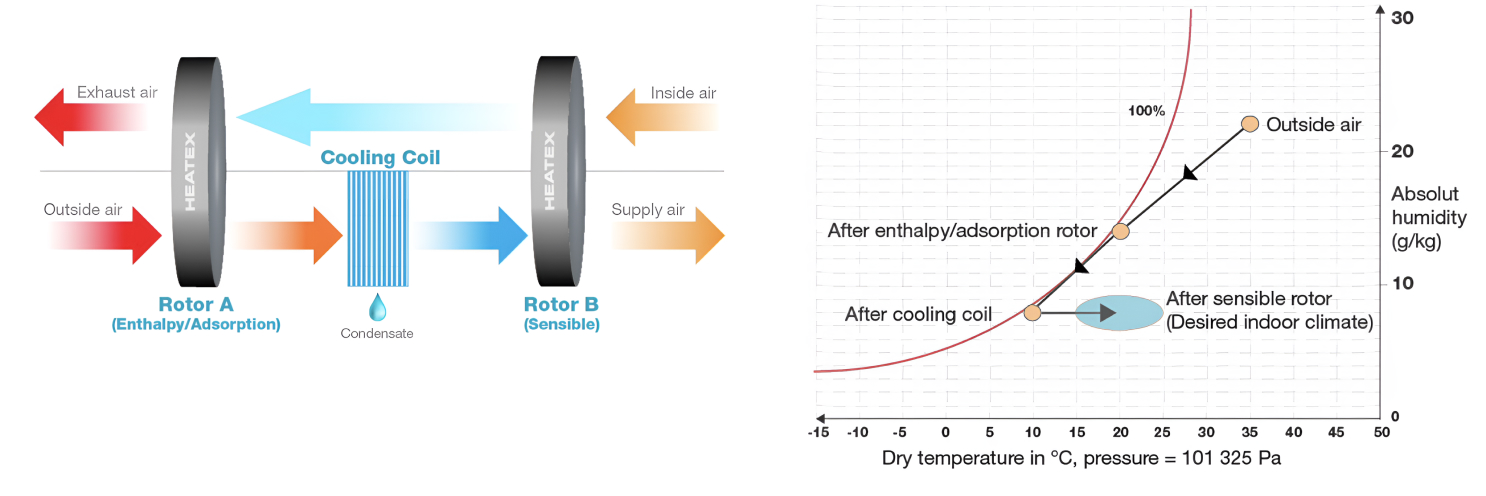

The double rotor concept is an energy-efficient solution for cooling and dehumidifying outdoor air for comfort ventilation applications. It uses highly efficient rotating heat exchangers with up to 90% humidity efficiency, where less or no reheating is necessary.

- Dehumidifying and Heating

The supply air must be cooled and dehumidified in regions with high air temperature and humidity. The double rotor concept is cooling, dehumidifying, and heating the supply air more energy effectively.

How a Double Rotor Setup Works

- The enthalpy/adsorption rotor dehumidifies and cools the hot and humid outside air.

- The cooling coil further dehumidifies the outside air until the requested humidity level is reached.

- The sensible rotor reheats the outside air to the required supply air temperature.

- At the same time, the exhaust air is cooled which increases the efficiency of the enthalpy/adsorption rotor.

Setup and Psychrometric Chart

Ask an Expert

If you aren’t sure about what type of heat exchanger you need, Contact Us. We are here to support you.