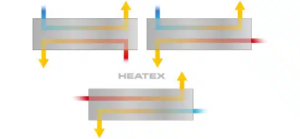

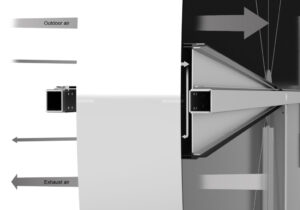

How does a crossflow heat exchanger work?

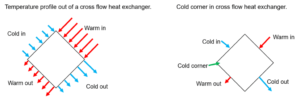

In a crossflow heat exchanger, the cold and the warm air flow perpendicular to each other. Two neighboring aluminum plates create channels for the air to pass through. The supply air passes on one side of the plate and the exhaust air on the other. The heat in the exhaust air is transferred through the plate from the warmer air to the colder air.

A very important parameter for the performance of a plate heat exchanger is the spacing between the plates. A narrow channel leads to high-pressure drop but also to high efficiency. The latter means that more heat is transferred to the cold side. A higher plate distance is better if a lower pressure drop is required. The trade-off is lower efficiency.

Usually, the exhaust air is contaminated with humidity and pollutants, but with a plate heat exchanger, airflows never mix, leaving the supply air fresh and clean.

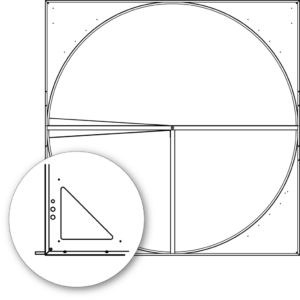

How does a rotary heat exchanger work?

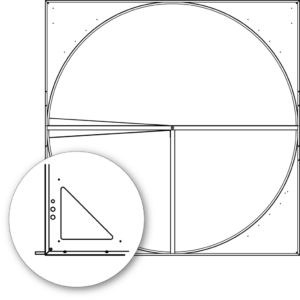

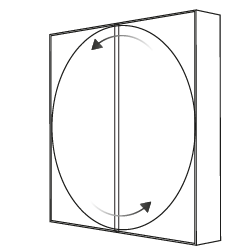

The wheel is built up by a matrix that consists of two foils, one flat and one corrugated; together, they create channels for the air to pass through. The wheel is rotated by an electric motor and belt drive system.

In one half of the rotation, the exhaust air from the inside space flows through the matrix. Its heat is stored in the matrix, and in the other half of the rotation, it is transferred to the fresh supply air from outside.

The size of the channel is called well height. Different well heights and diameters of the wheel give different efficiencies, pressure drops, and airflow rates.

Rotary heat exchangers that are properly constructed, installed, and maintained have almost zero transfer of particle-bound pollutants.

What is the difference between ERVs and HRVs?

ERVs transfer both heat and moisture, making them suitable for humid climates, while HRVs only transfer heat and are commonly used in colder climates.

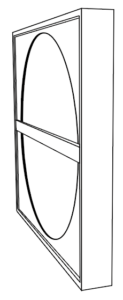

How does a counterflow heat exchanger work?

In the counterflow heat exchanger, two neighboring aluminum plates create channels for the air to pass through. The supply air passes on one side of the plate and the exhaust air on the other. Airflows are passed by each other along parallel aluminum plates instead of perpendicular like in a crossflow heat exchanger. The heat in the exhaust air is transferred through the plate from the warmer air to the colder air.

The exhaust air is sometimes contaminated with humidity and pollutants, but airflows never mix with a plate heat exchanger, leaving the supply air fresh and clean.

Terminology

Absolute humidity

Absolute humidity is expressed as either the mass of water vapor per volume of moist air (in grams per cubic meter) or the mass of water vapor per dry air (usually in grams per kilogram).

Adsorption

Adsorption is the adhesion of molecules in a gas or liquid to a solid material. This enables the removal and transfer of e.g. water molecules in the air (humidity transfer).

Humidity transfer can be done in rotor heat exchangers by coating the aluminum with either silica gel or molecular sieve. The coating absorbs humidity in one air stream and releases (desorb) the humidity in another air stream.

Adsorption material enables transferring not only heat but also moisture from one air stream to another.

Air tightness test

Air velocity

Airflow

Airflow Configuration

Application

AquaSeal

Heatex offers AquaSeal, a process that fills all plate crevices with a special polymer for water tightness and an even higher level of air tightness. This will result in a highly tight heat exchanger, suitable for applications with high humidity or direct water, such as adiabatic cooling and swimming pool applications. However, the level of tightness is only guaranteed if “individual air/water tightness test” is selected under options.

AquaSeal only applies to exchangers with plate spacing > 3mm (0.12”).

Heatex has confirmed that a max. temperature of 150°C during stable operating conditions is the upper limit. An individual evaluation is required for applications with large temperature fluctuations.

Brush seal

The brush seal features a double brush layer with an integrated plastic foil.

Bypass

A bypass is a standard option for plate heat exchangers. The purpose of the bypass is to, under certain conditions lead the air around but parallel to the heat exchanger, bypassing the plates. Reason for this could be capacity control or freeze protection.

Cable glands

Cable glands are used to lead cables from one side of a metal sheet to the other without affecting the environment on either side of the metal sheet since cable glands are usually airtight to a high level.

CE marking

We (Heatex) must not CE mark our product neither plate nor rotor. Plate heat exchangers are in this sense straightforward since they do not include any moving parts. And rotary heat exchangers, belong to the Machine directive which states that a “partly completed component” that cannot itself perform the application is not to be CE marked.

Condensate

Condensate is created when water is extracted from the air during the phase shift from gas to liquid. Condensation occurs when air is cooled to a dry temperature which is below the wet temperature and the relative humidity exceeds 100 %.

Condensate tray

Depending on the application you might want to add a condensate tray to collect and move water created by condensation out of the system. Heatex condensate tray is available for rotor heat exchangers and are made in stainless steel.

Corner profile

Corrosion protected framework

Covered casing

Damper

A Heatex damper is suitable for a closed/ open bypass exchanger section in connection with a cross flow heat exchanger.

Tightness classification 2.

Differential pressure

Differential pressure is the difference in pressure between the two air channels. It is often calculated as the difference between the heat exchanger’s supply air outlet and the exhaust air inlet. The differential pressure is used to calculate the leakage rate in the rotor heat exchanger and the impact on pressure drop for plate heat exchangers. Allowed values are up to 600 Pa for rotor heat exchangers and up to 1800-3000Pa for cross-flow heat exchangers (depending on the model). A positive value is used if the supply side has a higher absolute pressure than the exhaust side. A negative value is used when the exhaust pressure exceeds the supply.

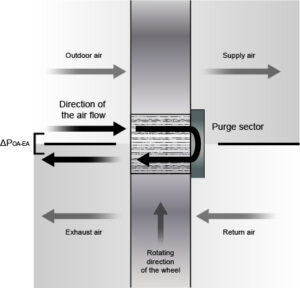

EATR and OACF

EATR is an abbreviation for Exhaust air transfer ratio. It represents the air mass leakage from exhaust air into the supply air. The main contributing factor to EATR is the carryover which is a consequence of the rotation of the wheel and thus the transport of the exhaust air trapped in the matrix. With the rotation of the wheel, the exhaust air enters the supply side. The EATR value is presented in % and shows the percentage of the exhaust air in the supply air.

OACF is an abbreviation for the Outdoor air correction factor. It basically shows how much supply air is lost in the heat recovery unit. The value is a ratio between the supply air inlet flow and supply air outlet flow. In ideal conditions, the ratio is 1. A value of 1.1 means that 10% more supply airflow is needed to compensate for leakages within the heat exchanger. An OACF below 1 means that exhaust air is leaking into the supply side

Eco-Design (ErP)

From January 1st, 2018, the demands on the minimum thermal efficiency of heat recovery systems in non-residential ventilation units rise from 67% to 73%. In addition, allowed pressure drop also decreases through the decreased SFP-value (internal specific fan power of ventilation components). These limitations make it essential to hit 73% while utilizing the allowed pressure drop to cover the most extensive possible flow range.

Effectiveness

Effectiveness takes into account the difference in mass balance. It is calculated by multiplying the efficiency times the specific mass air flow divided by the minimum airflow. Effectiveness describes how much of the available heat is transferred from one side of the heat exchanger to the other.

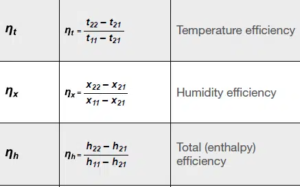

Efficiency

Efficiency describes how much e.g. the temperature changes from one side of the heat exchanger divided by the maximum theoretically possible temperature change. Efficiency can also be calculated for humidity and enthalpy.

22 = Supply from rotor, 21 = Supply to rotor, 11 = Exhaust to rotor

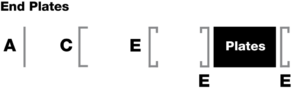

End plate

An end plate is a part of the casing on a cross flow heat exchanger. There is one end plate on each side of the plate package. Type E has a double folded edge, C is single folded and A is a flat metal sheet.

Energy efficiency and class

Energy efficiency and class are calculated according to EN 13053. The calculation adjusts thermal efficiency due to the total pressure drop. Heatex does this calculation without motor power consumption.

Enthalpy

Enthalpy is a property of a thermodynamic system and is equal to the system’s internal energy plus the product of its pressure and volume. The unit is often kJ/kg.

Epoxy

Epoxy is a resin of polyepoxide and is commonly used as a thin coating applied to a component to increase the protection from the surrounding environment (e.g. corrosion protection).

ErP

Exchanger orientation

Rotary heat exchangers

Vertical means the whole unit stands up at a 90° angle to the floor.

Plate heat exchangers

TBC

Free water

In a rotating heat exchanger condensation occurs when high temperature and high humidity air is cooled down. The condensate is either pushed out by the airflow or trapped in the matrix and by the rotation, it enters the other air stream. Some water is evaporated by this air stream and leaves the system with the air. The rest of the water, called “free water” trickles down the wheel/casing. A drip tray could be useful but in most cases, the free water is not an issue.

Freezing

Freezing in Plate Heat Exchangers

Tfrost < -xx°C indicates a high risk of freezing on the warm air side when the cold side inlet temperature is below -xx°C.

Heatex Select presents an outlet temperature on the warm air, but this is the average temperature. In reality, there is a temperature profile, with one side being colder than the other. A PHE has a cold corner where the cold air inlet and warm air outlet meet. The calculation for Tfrost is based on this temperature profile, the condensing temperature of the warm air, and the thermal efficiency. Note that there is only a risk of freezing if condensation occurs inside the heat exchanger. As a rule of thumb, freezing might occur if the sum of the leaving warm air temperature (from the PHE) and entering cold air temperature (to the PHE) is ≤ -2°C.

Freezing in Rotor Heat Exchangers

Rotary heat exchangers are less likely to freeze. The reason is that the rotor heat exchanger is continuously heated by the warm air, thus minimizing the risk of extensive freezing. However, if the cold air temperature is very low, the material temperature will be low enough to cause freezing on the side where the warm air is leaving the rotor.

Heatex does not have a recommended minimum temperature for supply air. It depends on the case. With the same mass flow on both warm and cold air side, one rule of thumb could be to use the average value of the inlet temperatures on the cold and warm sides. If this average value is below zero, installing a heater on the supply side or having a bypass arrangement might be a good idea to avoid freezing.

Humidifier efficiency

Humidifier efficiency is how well the air is humidified. 100% means the air is completely humidified, either by a wet pad or spray nozzle. The recommended value is 70%, depending on the wetting method and system design. Humidifier efficiency must be in the range of 20-100%

Hybrid

A hybrid rotor is consisting of a silica gel based coated flat aluminum coil and a corrugated aluminum foil. The purpose of this product is to improve the humidity transport compared to a pure aluminum rotor.

Inlet air pressure

Use the cogwheel to the right of the input field to adjust air pressure depending on elevation above sea level.

Inlet air pressure is the absolute air pressure at the entrance of the heat exchanger, usually around 101325 Pa.

Inspection hatch

For inspection and service, the rotor heat exchanger casing can be equipped with inspection hatches. E.g. an inspection hatch facilitates access to the drive unit.

Lacquered plate edges

Is an option provided by Heatex to seal the cut edges of the heat exchanger plates, that are coated with epoxy coating. This is a way to increase the corrosion resistance but this option can also be used to further tighten heat exchangers.

Matrix material

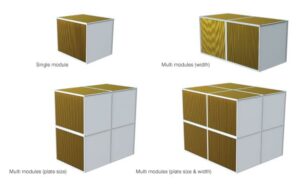

Modules

- For horizontal plates, the principle is the same: flip the whole module (s) 90°

Molecular sieve

Molecular sieve is the material used to achieve adsorption and thus a high humidity transport.

OACF

OACF is an abbreviation for Outdoor air correction factor. It basically shows how much supply air is lost in the heat recovery unit. The value is a ratio between the supply air inlet flow and supply air out- let flow. In ideal conditions, the ratio is 1. A value of 1.1 means that 10% more supply air flow is needed to compensate for leakages within the heat exchanger. An OACF below 1 means that exhaust air is leaking into the supply side

Plane of intersection

The plane of intersection is the orientation of the center beam that separates the two air streams. A horizontal orientation means one air flow in the upper part of the rotor and one in the lower. Vertical orientation means one air flow to the left and one to the right.

Plate distance

Also called “channel height”, it is the distance between the individual plates stacked upon each other. Bigger plate distance makes it easier to inspect and clean the heat exchanger in case of heavy pollution.

Plate size

The plate size is measured along the x or y axis (not diagonally).

Power belt

A Powerbelt is a special Heatex drive belt for rotary heat exchangers, developed to ensure easy adjustments and safe and reliable operation of the heat exchanger. Power belt is our toughest option and is highly wear-resistant. This belt is used without a tensioning device and can be used at temperatures up to 110°C (230°F) and in humid climates. The belt is easily joined together without any tools or locks and is, therefore, easy to maintain. The power belt is offered for all rotor diameters.

Power belt is a mandatory belt type for segmented rotor (model EQ) and model E when the special seal is used.

Pressure drop

Pressure drop is the reduction of absolute air pressure between the inlet and outlet of the heat exchanger’s air path.

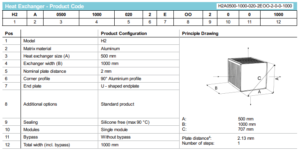

Product code

Product code is a code used to describe the configuration of a certain heat exchanger. However, additional features might only be visible in specific drawings.

Example:

Profiles

A profile is short for “corner profile”. Corner profiles are stays made out of aluminum, holding the entire heat exchanger together.

Purge sector

The purge sector is optimized to reduce carryover or EATR. It will stop the inlet of exhaust air in the small area right before airflows switch, thus avoiding exhaust air to get trapped in the matrix. a small amount of the supply air is used to blow out the minor amount of exhaust air that might have been trapped to ensure a fresh and clean supply air.

Relative humidity

Use the cogwheel to the right of the input field to convert absolute humidity to relative humidity or vice versa.

The relative humidity describes the saturation level of the air. When the relative humidity is 0 % the air is completely dry and when the relative humidity is 100 % the air is completely saturated, meaning that the dry temperature is the same as the wet bulb temperature and that condensation will occur if the temperature is reduced.

Rotational speed

Rotational speed describes how many revolutions a rotor will perform in a defined amount of time, usually measured in revolutions per minute or RPM.

Rotor depth

Rotor depth is the thickness of the wheel excluding the casing. Consequently, this is also the distance the air will pass through the matrix.

Round belt

The elastic round belt is easy to use since it requires no maintenance or tension device. The hollow endless belt is joined together by welding in Heatex production. If the belt needs to be rejoined, this can be done using a special pin delivered with the casing. The alternative is to change the belt to a power belt.

Sealing

Sealing is applied along the corner profiles of the plate heat exchanger to fixate the individual plates. Depending on the temperature of the application, different sealing properties are needed.

Silica gel

Silica gel is a coating material used on rotating heat exchangers to achieve adsorption and thus high humidity transport.

Special brush seal

The special brush seal is a wear-resistant seal that reduces leakage on rotary heat exchangers. Its brush fibers are made of a special polymer that allows for better wear resistance against the wheel, and the rubber lips on both sides reduce the leakage to a minimum.

Steps

The number of steps describes the number of individual plate heat exchangers mounted after each other. There are “diamond” and side by side” configurations.

Temperature

The ambient or outdoor temperature usually decides the temperature of the supply air. The temperature of the exhaust air generally decides the indoor air temperature.

Transferred power

Transferred power is the amount of energy transferred per time unit (e.g. kW) between the two sides of the heat exchanger.

Uneven airflow

Uneven airflow is a way of indicating that the incoming air’s speed gradient is not equal over the entire cross-section of the heat exchanger inlet.

Well height

The well height definition was standardized by the Eurovent organization and is defined as flat foil thickness plus total wave height.

Water tightness test

As standard, for every heat exchanger applied with AquaSeal, a water tightness test is performed at 400Pa (1.6” WC) for 20 minutes. The exchanger is tested on all four sides.