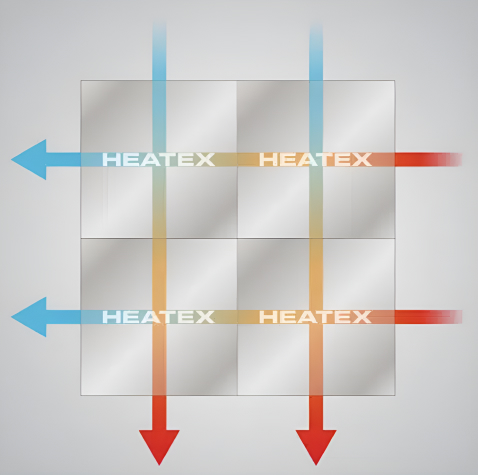

HEATEX crossflow heat exchangers are carefully designed to meet the demands of each specific application and maximize energy recovery.

High Efficiency

Up to 90% of the heat in the exhaust air is

transferred to the supply air.

Easy Maintenance

The design allows for rapid and thorough

cleaning and servicing.

Longevity

No moving parts and strong heat transfer

plates guarantee a long lifetime.

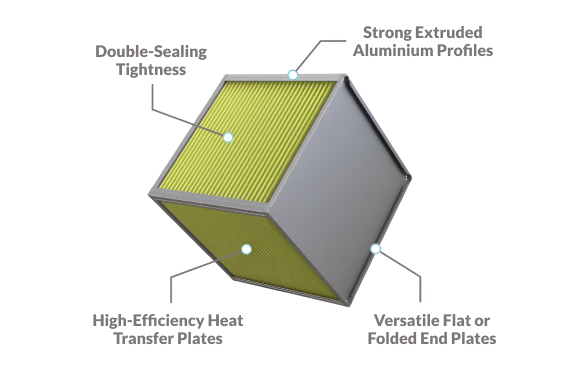

Cross Flow Plate Type Air to Air Heat Exchanger Features

All Heatex crossflow heat exchangers share these features:

- Extruded aluminium corner profiles (stainless steel is optional).

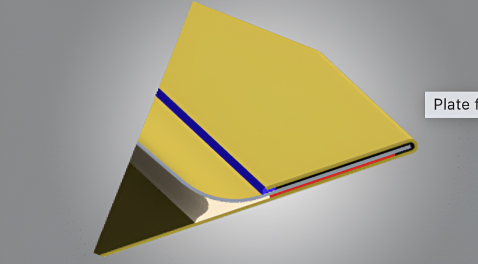

- Double-sealing concept to avoid leakage and contamination, which means both gluing and a mechanical fold.

- Heatex’s corrugation pattern increases turbulence and heat transfer without creating stagnation points.

- End plates with flat or folded edges for all mounting interfaces.

Depending on the application, you might need a certain crossflow model, including options.

Choose Your Model

Every Model has a clear advantage, depending on your application.

| Heatex Model | H2 | H | P | Z |

|---|---|---|---|---|

| Description | Outstanding efficiency for commercial ventilation and high-performance cooling. | Particular low pressure drop for basic ventilation and cooling applications. | Extra differential pressure resilience for industrial ventilation applications. | Exceptional durability and corrosion resistance for very tough applications. |

| Efficiency | Superior | High | High | High |

| Airflow capacity | Standard | High | High | Standard |

| Heat transfer plate material |

|

|

|

Stainless steel |

| Combined modules size | 500 – 3000 mm (19.69″ – 118.1″) |

200 – 3000 mm (7.87″ – 118.1″) |

600 – 3000 mm (7.87″ – 118.1″) |

600 & 1200 mm (23.62″ & 47.24″) |

| Max. differential pressure | 3000 Pa (12.04 “WC) | 1800 Pa (7.23 “WC) | 3800 Pa (12.26 “WC) | 4000 Pa (16.06 “WC) |

Options

Besides being able to configure each heat exchanger in numerous ways in terms of size and performance requirements, we offer a wide range of options to suit various applications.

Corrosion Protection

We recommend adding epoxy-coated heat transfer plates, a corrosion-protected framework, and lacquered plate edges for improved corrosion protection in demanding applications such as in coastal environments.

Dampers

Dampers are useful for protecting the heat exchanger when the heat exchanger approaches the freezing point. Heatex dampers are suitable for close / open bypass exchanger sections connected to a crossflow plate heat exchanger.

Extra Tightness with AquaSeal

Heatex offers a process for filling all plate crevices with a special polymer for water tightness and an even higher level of air tightness. This will result in a highly tight heat exchanger suitable for high humidity or direct water exposure.

Product Selection with Heatex Select

Heatex Select enables accurate calculations of the performance of our products under different conditions. Heatex Select is accessible in three ways, online, offline and as a DLL.

Certified Performance

Our products always comply with standards, always perform according to (or even exceed) codes and specifications. Heatex holds several certifications covering product and operation quality worldwide, e.g. Eurovent, AHRI, and TüvSüd. Our products are field-tested and designed to comply with all relevant building codes and regulations. We frequently send our products to independent labs worldwide for inspection and we have our own in-house test rig to regularly evaluate product performance.

Application

Crossflow heat exchangers are very versatile and can be found in a wide range of applications. These are just a few examples.

Commercial Ventilation

Data Center Cooling

Wood Drying

Spray Paint Booths

Indoor Agriculture

Wind Turbine Cooling

Industrial Ventilation

Thermal Management

Solar Inverter Cooling

Residential Ventilation

Dehumidification

Comfort Ventilation

Rotary & Plate Heat Exchangers

Heatex quality air-to-air heat exchangers are custom-made and designed to match the customer’s technical specifications. There are two categories of air-to-air heat exchangers, rotary and plate heat exchangers. The plate heat exchangers are further divided into cross and counterflow exchangers due to their different airflow configurations. Depending on the application, rotary and plate heat exchangers have their own distinct advantages.

| Rotary Heat Exchangers | Plate Heat Exchangers |

|---|---|

| Low risk of freezing | Very low leakage rate |

| Humidity transfer | No moving parts |

| Leaving a small footprint in air direction | Minimal service and long lifetime |

| High flow rate capacities | Rapid and easy cleaning |

Ask an Expert

If you aren’t sure about what type of heat exchanger you need, Contact Us. We are here to support you.