Barcol-Air seeks to create an indoor climate which offers an optimum in terms of comfort and energy efficiency. The company has grown its reputation and worldwide operations based on their expertise in commercial air conditioning system and component design with emphasis on advanced low energy systems particularly.

Barcol-Air patented design has 2×12 sensing points with signal averaging and amplification with proven accuracy of 2.5% even with irregular duct approach.

Controllers are normally factory calibrated with maximum and minimum and heat airflows for plug and play operation.

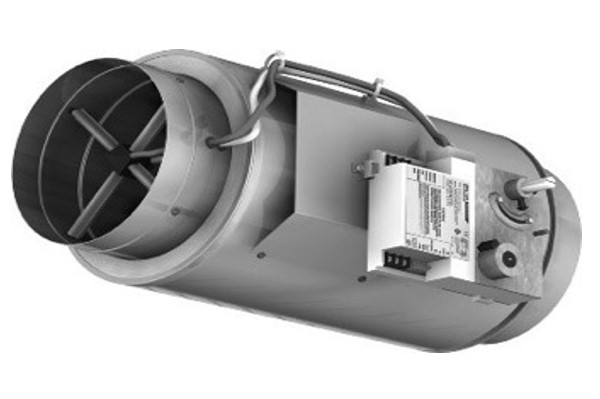

Variable Air Volume (VAV) Terminal Configurations